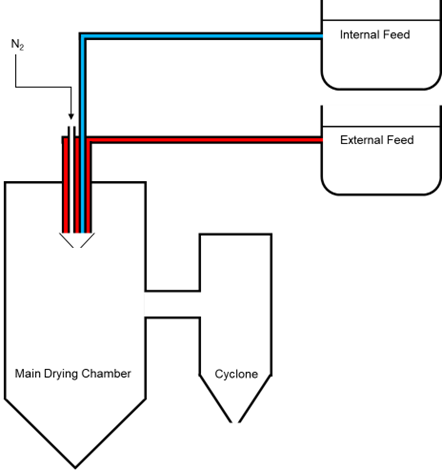

Dr Hisham Al-Obaidi has developed two and three fluid spray drying technologies to streamline current manufacturing processes and eliminate many of the current steps used in spray drying. This technology has the following benefits:

- API’s can be engineered to their required form directly from synthesis to achieve maximum efficacy. This cuts out lengthy processing steps such as mixing, drying, sieving and micronisation. In a single production step API particles are engineered to their required shape and size for a given end application (for tableting, inhalation and powder form for capsules).

- Manufacturing costs can be reduced significantly through smaller manufacturing lines, the possibility of continuous processing, reduced labour and energy costs and less waste.

- Using spray drying technology, API particles can be coated with a great level of precision thus improving coating consistency and increasing control over release rate properties.

This technology at the University of Reading will streamline processing and improve final product quality. It has potential applications in the pharmaceutical, chemical, food and nutraceutical industry. The main advantages of spray drying include:

- Low production costs.

- Shorter production times based on continuous flow processing.

- Simpler coating processes of final API to control drug release rates.