Dr Sarah Needs and Dr Sophie Jegouic, biomedical engineers at Reading, have designed and built a low-cost robot that takes high resolution images of experiments to speed up tests for antibiotic resistance and COVID-19 antibodies. Here, for #INWED20, they explain how they are using open source hardware, 3D printing and a raseberry pi computer to address these global challenges.

Biomedical Technology Lab at Reading

Our Biomedical Technology Lab builds simple low-cost solutions for current and future healthcare problems. We are a team from a biological sciences background and are embracing interdisciplinary working, developing new technologies to tackle global challenges ranging from antimicrobial resistance to Covid-19 testing.

Rapid prototyping is the process we use to quickly make physical models using computer-aided designs. We mainly use 3D printing and low-cost electronics to make and test imaging systems designed to be compatible with the bioassays we are developing. Commercial printers are increasingly affordable and allow the design of a new piece of equipment and to print it within a day.

Antimicrobial resistance tests

Antimicrobial resistance is a global challenge and threatens the effective treatment of infections caused by bacteria. I (Dr Sarah Needs) am a postdoctoral researcher in Dr Al Edwards lab in the School of Pharmacy, and am using these techniques to develop rapid antimicrobial resistance tests.

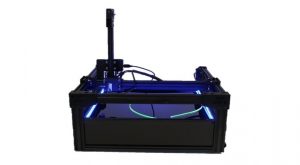

Traditional microbiology techniques can take 48 hours to determine antibiotic resistance. However, using micro-devices and following a colour change which corresponds to bacterial growth, this can be identified within hours. To help in this study we developed the POLIR, (Raspberry Pi camera Open-Source Laboratory Imaging Robot). This system was developed based on designs for 3D printers with the addition of a raspberry pi camera.

Using this design, the raspberry pi camera can move around the imaging area and take pictures of the experiment at different locations and times, allowing high resolution time-lapse imaging. This allows over 2000 individual tests to be screened in a single experiment. In June 2019 we successfully installed a POLIR in Universiti Teknologi Malaysia for use with microbiology tests.

Using the robot in our lab, we have decreased the amount of time spent in-lab for researchers, while increasing the quality and quantity of so-called kinetic data. Our hope is that other laboratories can implement versions of this open hardware solution to reduce the amount of time spent imaging in the lab by researchers.

Covid-19 Antibody Tests

Dr Sophie Jegouic, a postdoctoral researcher in biomedical sciences, has been using similar techniques using raspberry pi cameras and 3D printed components in the development of rapid COVID-19 antibody tests. Currently, most Covid-19 tests detect viral RNA using a technique called PCR, and can only identify if someone has an active infection. Antibody tests allow the detection of Covid-19 antibodies in the blood which can identify if someone has had an infection in the past.

There are two types of tests available; laboratory tests, which tend to be accurate but require a significant amount of equipment and user-training or rapid tests that are cheaper and can be performed outside of a lab, but tend to be less accurate.

We have been working on tests that are more portable than laboratory tests but still as accurate. The test involves coating micro-devices with a viral protein. This protein alone is not infectious, but allows antibodies in a blood sample to bind to it. The amount of antibody binding can then be measured by the fluorescent output which is linked to the amount of antibody present.

While the laboratory experimental setups measuring these types of tests require expensive and bulky laboratory equipment, we use an imaging setup designed in-house and 3D printed. This can also be used with a smartphone camera, potentially allowing this test to be done outside of a lab.

Rapid prototyping means we can develop new bioassays quickly, responding to real world challenges.