In this blog for World Vegan Day, Dr Dimitris Balagiannis, Senior Research Fellow at the University of Reading Flavour Centre, explains how a new research consortium is embracing cutting-edge fermentation technologies and circular economy principles to overcome the challenges holding back plant-based meat alternatives.

Around 10–15 years ago, brands such as Impossible Foods and Beyond Meat entered the US market offering burgers made entirely from plant-based ingredients that closely replicated the taste and texture of real meat. This innovation was followed by a surge of investment in research, startup activity, and new product development in the alternative protein sector.

However, this was not the first time that products mimicking meat had appeared. Their origins can be traced back to around 206 BC, when evidence indicates that tofu, a product based on soya beans, was consumed in ancient China.

Another example dates to the mid-1960s, where British scientists developed a meat-like protein from fungi, now known as mycoprotein, which became the basis for the well-known brand Quorn.

With the recent rise in plant-based alternatives, supermarkets introduced dedicated sections to accommodate the novel products. Their market share grew steadily, and a positive outlook was projected.

Recently, however, growth has slowed and sales have plateaued. Yet there are reasons for optimism – breakthroughs in fermentation and sustainable food production are paving the way for a new generation of products that are tastier, less processed, and more sustainable and nutritious than ever before. With the right combination of technological innovation and consumer engagement, these advances could usher in a new era of growth.

Why we need better plant-based meat

Meat analogues are promising alternatives for our diets with several benefits for our health, animal welfare and the environment.

Choosing meat alternatives over real meat reduces our reliance on animal farming, which is responsible for emitting significant amounts of greenhouse gases. The shift toward plant-based options also addresses animal welfare issues related to traditional livestock farming while advancing human welfare. Meat substitutes can be engineered to deliver high-quality protein without saturated or trans fats (responsible for increased cholesterol levels in the blood), and they can be fortified with beneficial nutrients. As the global population grows, such innovations are crucial for ensuring a sustainable and sufficient protein supply, which animal farming cannot guarantee.

From a social perspective, meat substitutes appeal to a wide range of consumers: omnivores and flexitarians, those on restricted diets (e.g. vegetarian, vegan, religious), and even those who due to health issues cannot consume real meat.

The meat analogue sector also supports the circular economy, since these products can be formulated with ingredients produced by upcycling food by-products. This in turn reduces food waste, boosting their sustainability credentials.

What’s holding plant-based meat back?

Even though the benefits of introducing meat alternatives to our diets are well established, consumers remain sceptical. The main reasons are poor flavour, high prices and extensive ingredient lists with lots of food additives.

Indeed, real meat products are still cheaper than their vegan substitutes, while the producers and developers of the latter have not yet managed to convincingly replicate the authentic meat flavour, which often presents undesirable off-notes.

Moreover, low versatility and lack of flavour diversity have hindered consumer interest, while the large number of ingredients required to produce products that mimic meat, several of which are considered food additives or ultra-processed, puts consumers off.

How new technologies are changing the game

The future of meat alternatives is promising, with new initiatives and technologies in the pipeline that aim to re-attract consumers’ attention. These innovations directly tackle the flavour, cost and processing challenges that have limited plant-based meat’s appeal.

Cultured meat is an emerging technology where cells taken from animals are lab-grown into meat cuts with authentic flavour. These products were recently licensed and launched in Singapore, the United States and Israel. However, their vegan status is questionable since they are formed from animal cells.

More promising for the plant-based sector are significant efforts and investment focused on fermentation technologies to produce protein from fungi or other microorganisms. Fermentation – where microorganisms are fed on waste materials to produce protein-rich biomass – is viewed as a sustainable source of alternative protein that supports a circular economy. It utilises food waste and by-products as raw materials and requires fewer additives to create flavourful meat alternatives.

Finally, hybrid products – which combine plant-based ingredients with cultured or fermented proteins – are also gaining traction. These blends can achieve a more authentic meat-like experience while reducing production costs and minimising heavy processing.

Putting theory into practice

A team of scientists from across Europe has identified the potential of fermentation and hybrid technologies, and joined forces in a consortium named PLANTOMYC to tackle the associated manufacturing and market challenges.

The goal is to produce innovative, minimally processed, flavourful and nutritious meat substitutes, that meet consumer demands, based on plant-based ingredients, fermentation advances and hybrid technologies. The consortium has recently attracted funding from the Horizon Europe programme to fulfil these ambitions.

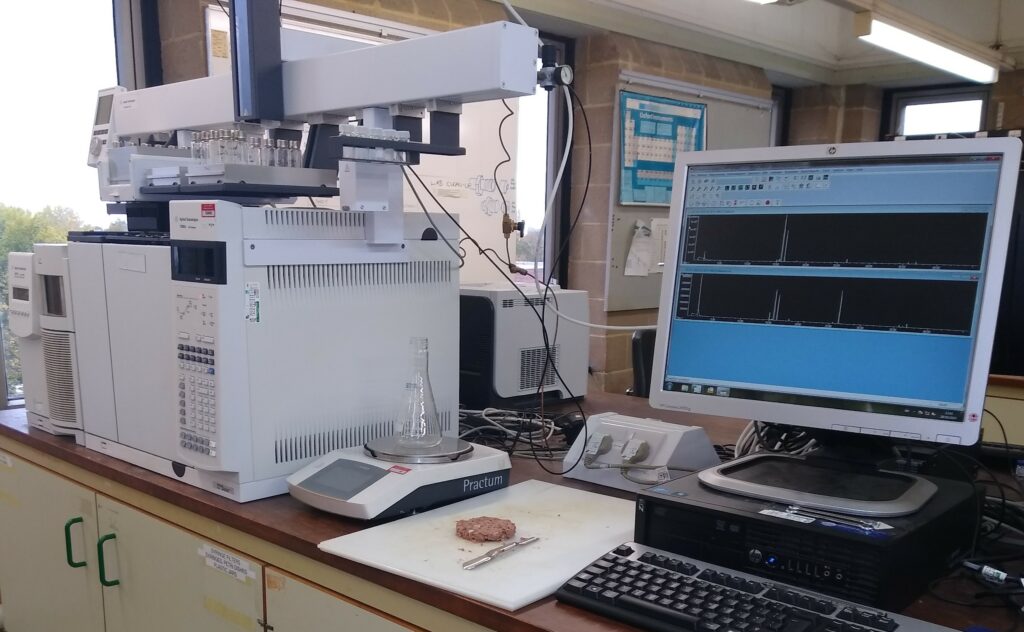

Here at Reading, we’re playing a central role in PLANTOMYC due to our strong expertise in flavour chemistry and sensory and consumer sciences. Our team provides expertise in developing products with appealing flavours while avoiding off-notes, conducts sensory and consumer studies to assess product appeal and quality, and performs chemical analyses of raw materials and final products.

Our work also includes innovative product development, through the creation of a savoury bouillon – which can be used in soups, stews, and as a flavour base for home cooking – from upcycled waste materials.

At the heart of PLANTOMYC’s ethos is sustainability and circularity. Meat analogues will be developed from innovative precision fermentation processes that upcycle materials from waste streams, including brewers’ spent grain (waste from beer production) and pea-protein residue (a by-product from the production of protein isolated from peas).

To minimise waste from the production of the PLANTOMYC meat substitutes, the Reading team is employing upcycling practices to develop a meat-flavoured bouillon. In addition, partner teams will use the by-products of mycoprotein processing to isolate gamma-aminobutyric acid (GABA), a healthy bioactive known for its neuroactive and metabolic effects, and formulate a GABA-enriched beverage.

A tastier, more sustainable future

This World Vegan Day, the plant-based meat sector stands at a pivotal moment. The challenges that caused growth to plateau – lacklustre flavour, high costs and concerns about overprocessing – are being directly addressed by innovative technologies like precision fermentation and circular production methods.

Projects like PLANTOMYC demonstrate what’s possible, offering a glimpse of a food system that’s kinder to animals, better for the planet and more appealing to our taste buds.

That’s something worth celebrating, whether you’re vegan or not.

This project has received funding from the European Union’s Horizon Europe Research and Innovation program under Grant Agreement No 101181982 and by the Swiss State Secretariat for Education, Research and Innovation (SERI). For more information and updates on the progress of the project please follow PLANTOMYC:

Website: https://plantomyc.eu/

Linkedin: https://www.linkedin.com/company/plantomyc/

Cover image by Cosmin Ursea on Unsplash